The fourth generation TRENCH MOS

Process technology

Provide practical solutions based on the needs of different customers.

Productioncapacity

World-class 8-inch production line

The fully automatic production equipment optimizes the process, saving 30% of labor.

Both wafers and packaging are produced by leading domestic manufacturers and manufactured on an 8-inch production line equipped with world-class facilities. Quality is guaranteed through multiple processes, and the entire production process is traceable.

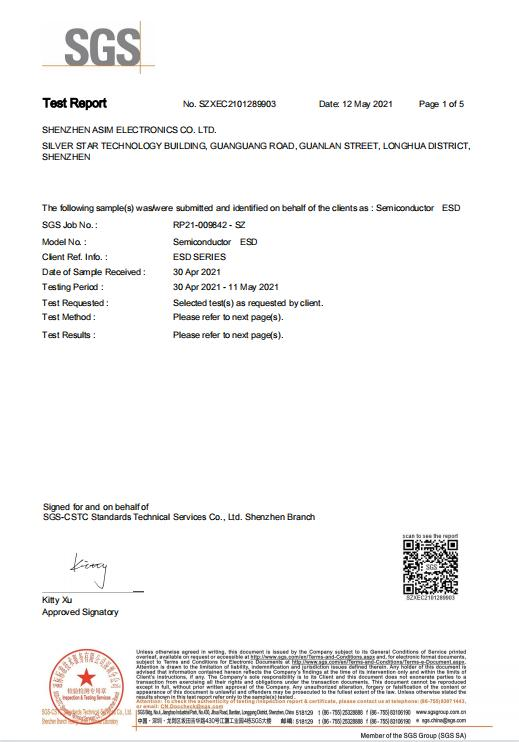

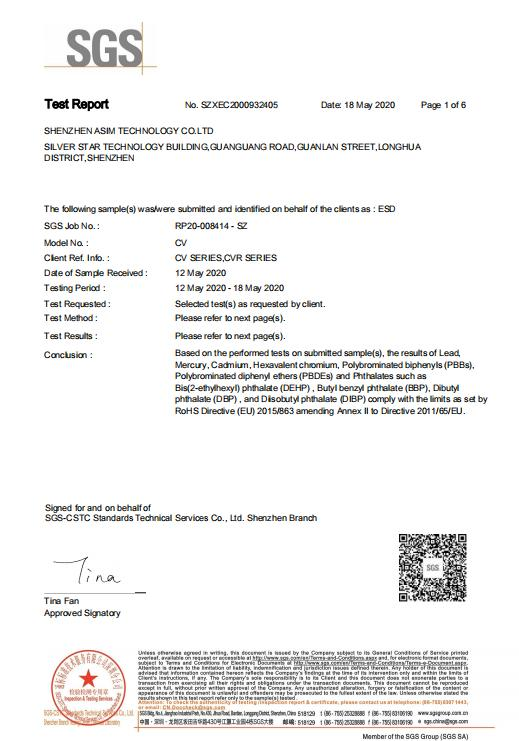

First-class production and testing equipment, and all product materials have passed the RoHS test.

All performance indicators of the product are at the leading level in the industry. The production capacity and scale are strong, and the delivery time is guaranteed.

Ourquality testing

Create high-performance and high-quality EMC protection devices for the electronics industry

Test Item Abrv

Reference

Stress Condition

Sample Size/ Lots

End Point

ESD-HBM

ANSI/ESD STM5.1 AEC-

Q100-002

R=1500Ω,C=100pF,U= Situation imposition (100~20000V) Apply according to the actual situation of the product

Damage after ESD

ESD-MM

ANSI/ESD STM5.1

AECQ100-002

R=0Ω,C=200pF,U=(100~4000V),Apply according to the actual situation of the product

PC

JESD22-A113

Per device Specification Baking-THT(30℃ / 60%RH,

192hours or 60℃ / 60%RH,40hours)→IR(260℃,3cys);

or 125℃ / 24H→THT(85℃ / 85%RH,168hours)→IR(260℃,3cys)

SMD All Parts for TH,TC,UHAST / PCT,H3TRB / HAST

Pre- Electrical Test;

Post- ElectricalTest;

Pre-SAT; PoSt-SAT

HTSL

JESD22-A103

R=1500Ω,C=100pF,U=(100~20000V),Apply according to the actual situation of the product

0,168,500,1000hours

TH

JESD22-A104

Ta=85°C,RH=85%

0,100or200,500,1000cycles

TC

JESD22-A104

Ta =-55°C/15min, to 2~5min, to +150℃ /15min

0,100or200,500,1000cycles

JESD22-A118

JESD22-A104

Ta =130°C; 85%RH

0,96hours

HTRB

JESD22-A108MIL-

STD-750F-1038.5

GBT 4938-1985

Field-effect transistor:Ta=150℃,V=(VDSS Max)*(80%~100%)

Transistor:VR=(80%~100%)*(VDSS Max)*(80%~100%)

Voltage stabilizing diode:VR=VZ Max*(80%~100%)

Thyristor:VR=(VRRM Max)*(80%~100%)

Schottky tube:Ta=85℃,VR=(VRRM Max)*(80%~100%)

0,168,500,1000hours

AC/PCT

JESD22-A102

Ta=121℃, 29.7psig, 100%RH

0,96hours

RSH

JESD22-A 111 (SMD)

JESD22-B 106 (PTH)

SMD:Ta=260°C,10 seconds PTH:Ta=270°C,10 seconds

一

J-STD-002

①PC : Dry Bake 155°C/4hours±15min) Or Dry Bake150°C/16hours±15min)Or Steam 4 Hours±10min

②SMD:Reflow Soldering:Ta=245±5°C,5+0/-0.5 seconds ;

PTH:Wave Soldering : Ta=260°C +5/-0°C,5 +2/-1seconds

一

TS

MIL-STD-750

Method 2036

一

OLT

JESD22-A108

Transistor:Vc=70%VCEO,IC=PC/VC Voltage stabilizing diode:VC=VZ+1V,IC=Iz Three-terminal voltage stabilizing diode:VC=VO+1V,IC≤100mA

0,168 500,1000hours

HTGB

JESD22-A108

Ta=85°C to 150°C,VGS=(VGS Rating)X80%(仅MOS )

0,168 500,1000hours

H3TRB*

JESD22-A101

Ta=85°C RH=85%,VR=(VDS Rating)X80%(Only discrete devices)

0,168 500,1000hours

HAST*

JESD22A-110

Ta=130'C/85%RH,T=96 hours,V=80%VMAX Ta=110°C/85%RH,T=264hrs,V=80%VMAX,The highest is 100V

0,96hours

IOL*

MIL-STD-750 Method 1037

case:Ton=120s,Toff=120s,15000cycles(Only discrete devices)

0,15000hours

| Project | Non-automotive grade 2SC2383T | Automotive grade BR2SC2383TQ | ||||

|---|---|---|---|---|---|---|

Test item |

Minimum value |

Maximum value |

Test conditions |

Minimum value |

Maximum value |

Test conditions |

VCE(SAT) |

50mV |

1.050V |

IC=500mA, IB=50mA |

102.5mV |

132.3mV |

IC=500mA, IB=50mA |

BVCB0 |

165V |

500V |

IC=100uA |

427.8V |

447.8V |

IC=100uA |

BVEB0 |

6.5V |

20V |

IE=100uA |

11.52V |

11.84V |

IE=100uA |

ICB0 |

0 |

80nA |

VCB=150V |

0 |

7.533nA |

VCB=150V |

IEB0 |

0 |

80nA |

VEB=6V |

0 |

10.18nA |

VEB=6V |

BVCE01 |

165V |

400V |

IC=500uA |

204.5V |

231.1V |

IC=500uA |

BVCE02 |

120V |

400V |

IC=15uA |

203.7V |

232.5V |

IC=15uA |

DIVID |

0 |

1.065 |

BVCEO1/BVCEO2 |

0.9912 |

1.006 |

BVCEO1/BVCE02 |

ICE0 |

0 |

2.5uA |

VCE=165V |

128.9nA |

317.6nA |

VCE=165V |

HFE1 |

60 |

320 |

VCE=5V,IC=200mA |

131.3 |

197.8 |

VCE=5V,IC=200mA |

HFE2 |

50 |

320 |

VCE=5V,IC=20mA |

135.7 |

197.6 |

VCE=5V,IC=20mA |

DIVID |

0.73 |

2 |

HFE2/HFE1 |

0.9828 |

1.043 |

HFE2/HFE1 |

VFBC |

650mV |

850mV |

IB=10mA |

745mV |

800mV |

IB=10mA |

VFBE |

650mV |

850mV |

IB=10mA |

744.3mV |

800mV |

IB=10mA |

The testing of automotive-grade products is managed online through PAT. The test data is statistically analyzed to remove products outside the group from the good product specifications

Max static limit = robust mean + 6*(robust sigma)

Min static limit = robust mean - 6*(robust sigma)

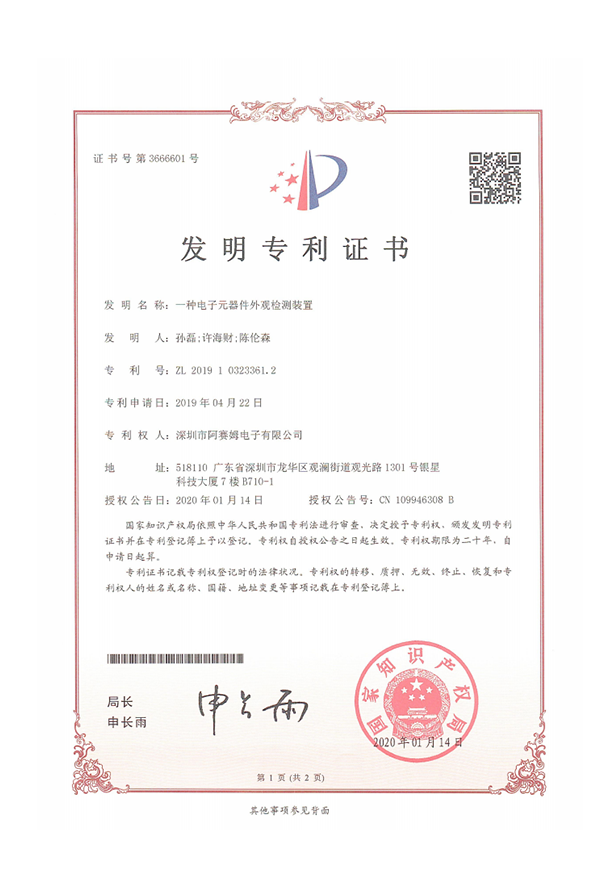

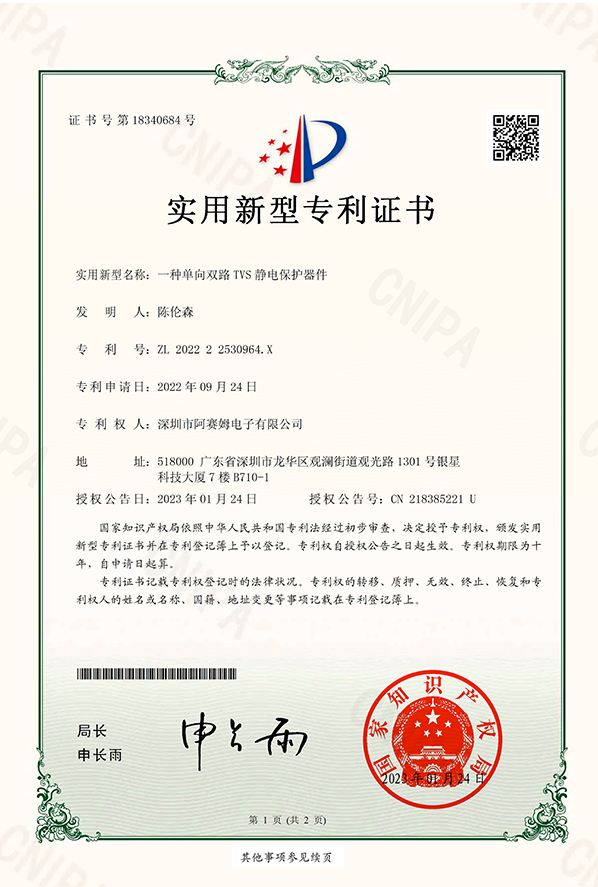

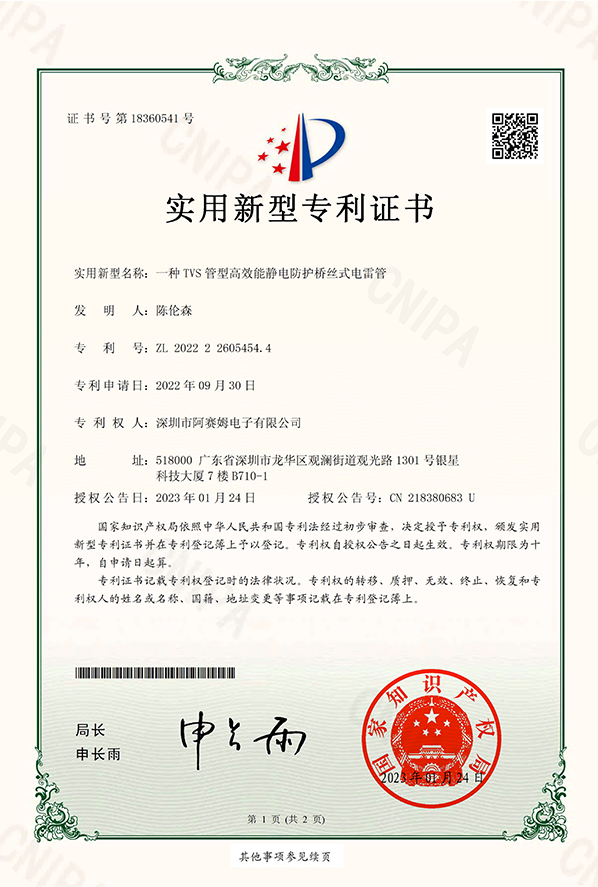

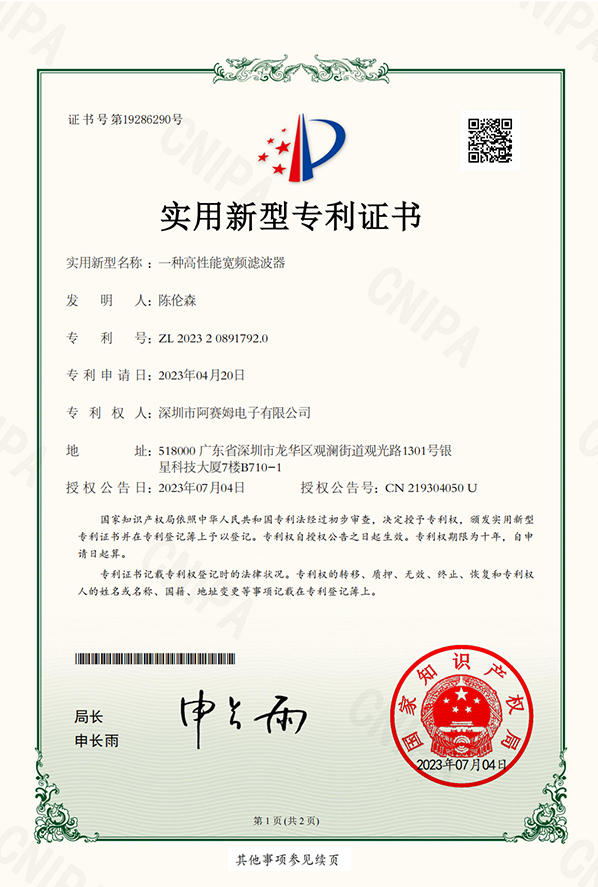

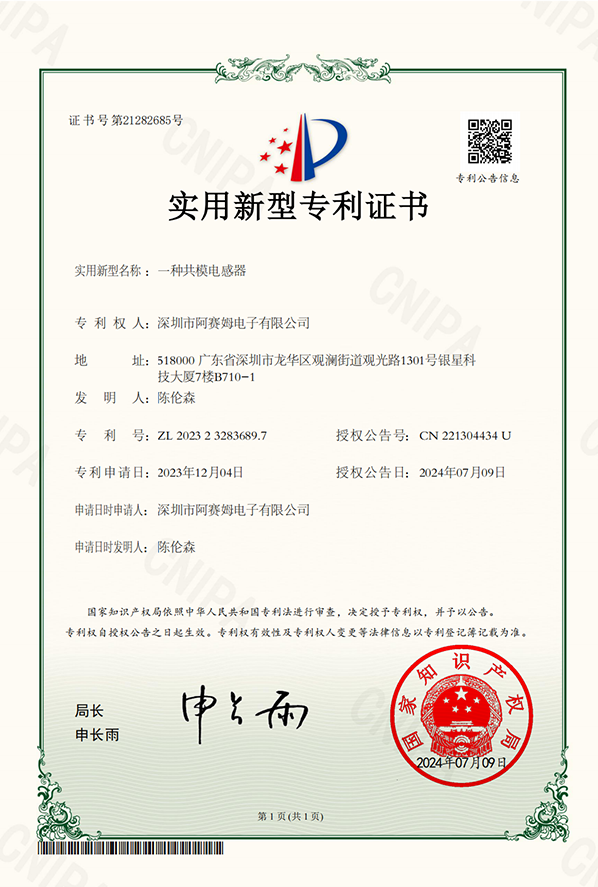

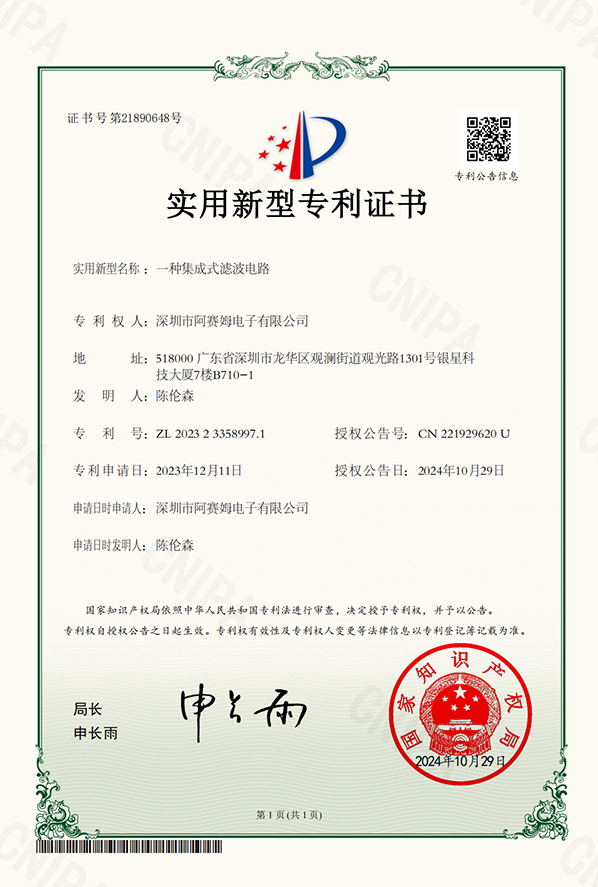

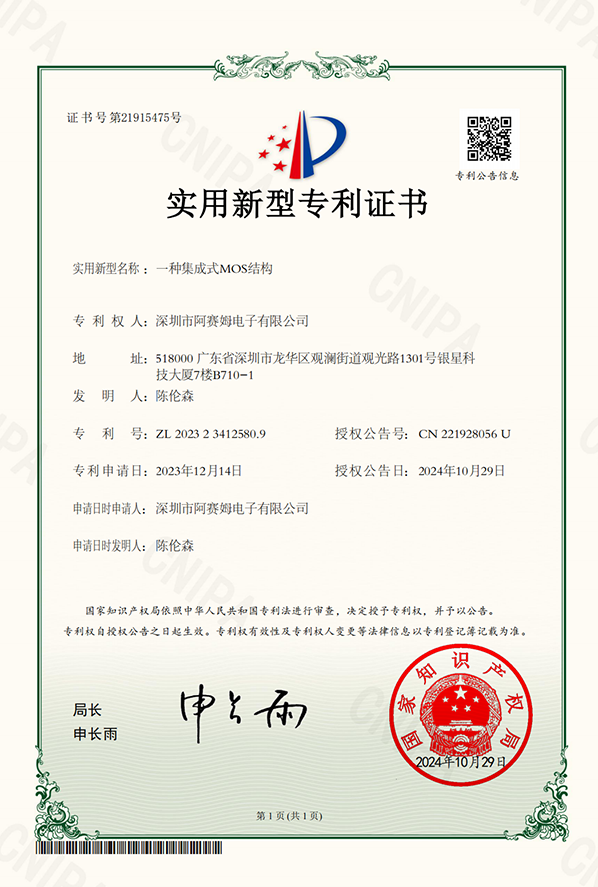

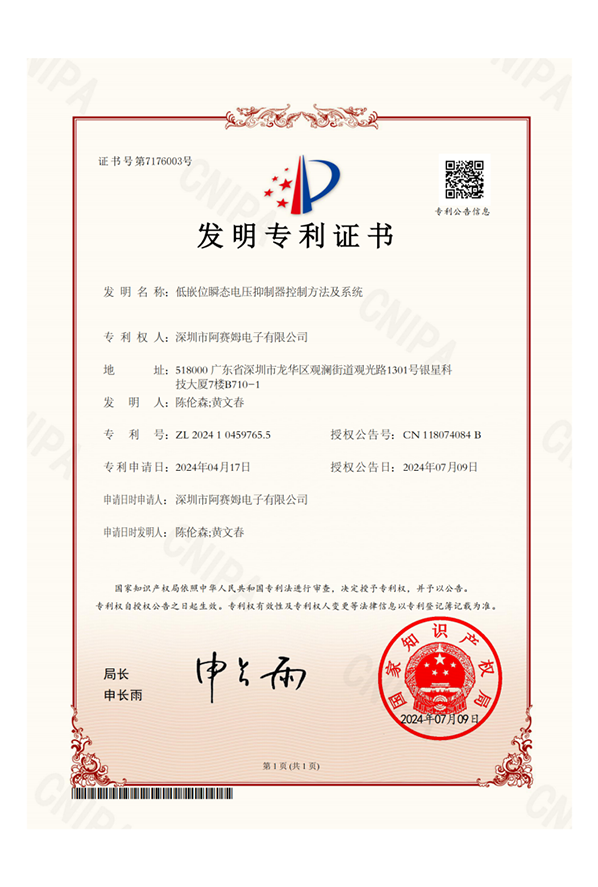

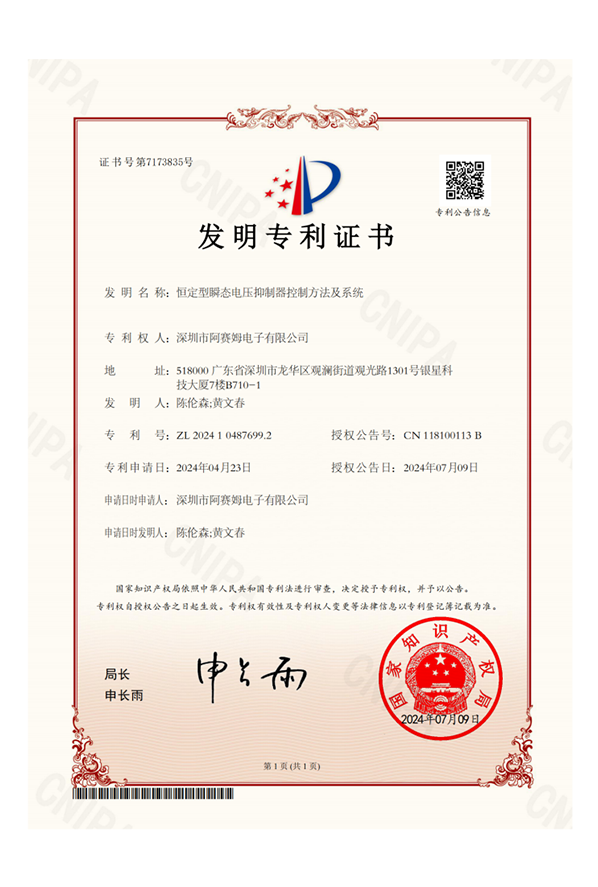

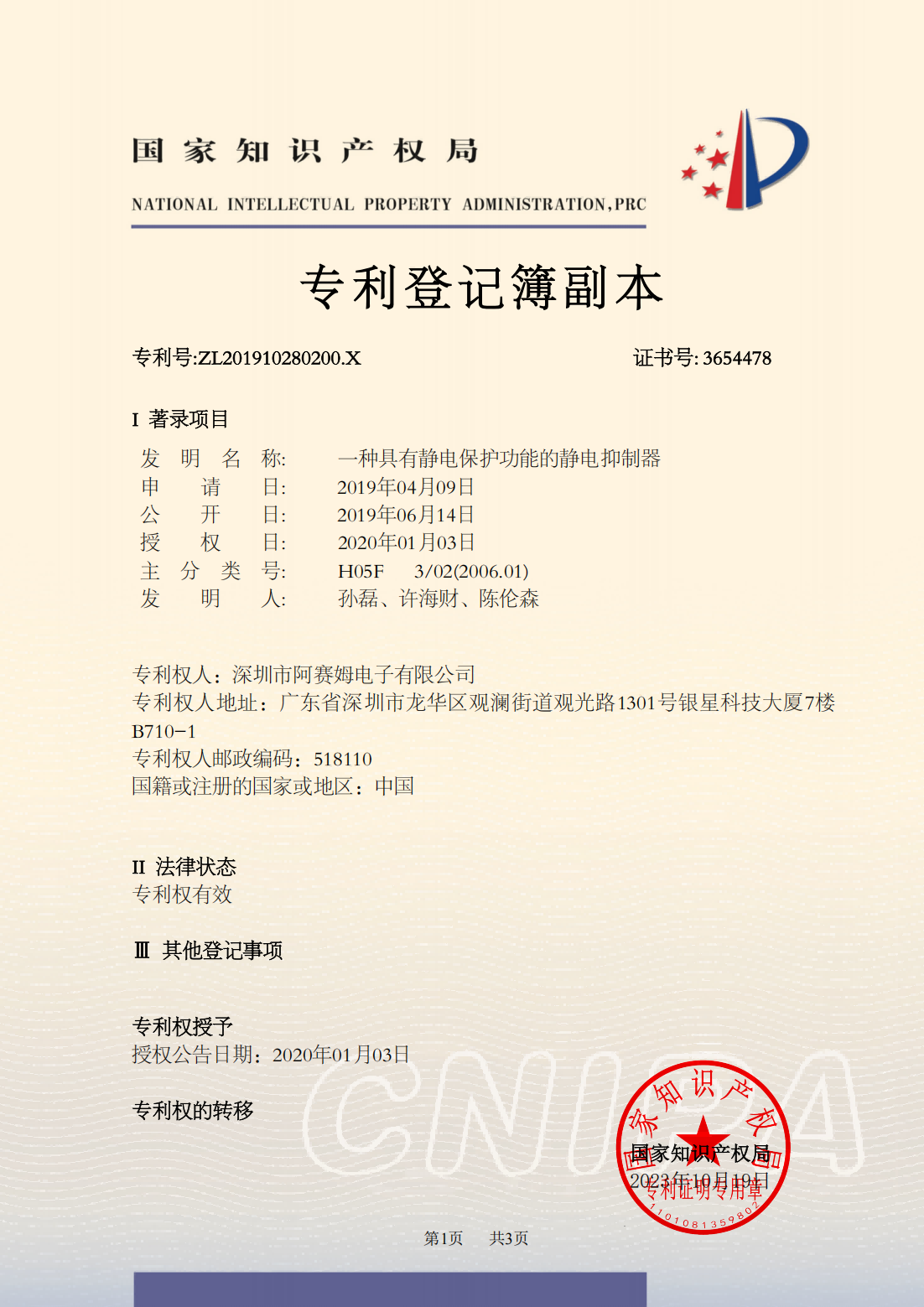

Strong scientific research capabilities,Elite team

Professional R&D team

Senior engineer

Professional design team

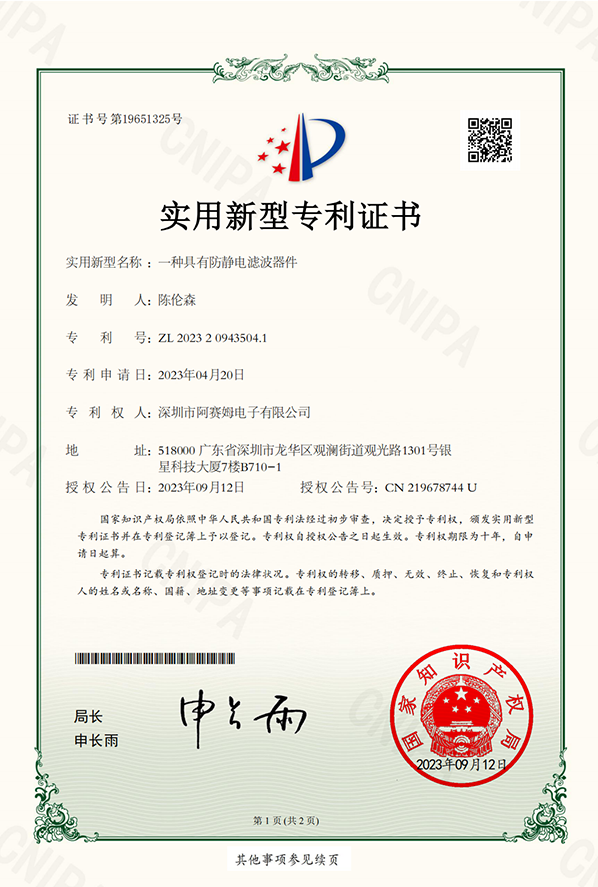

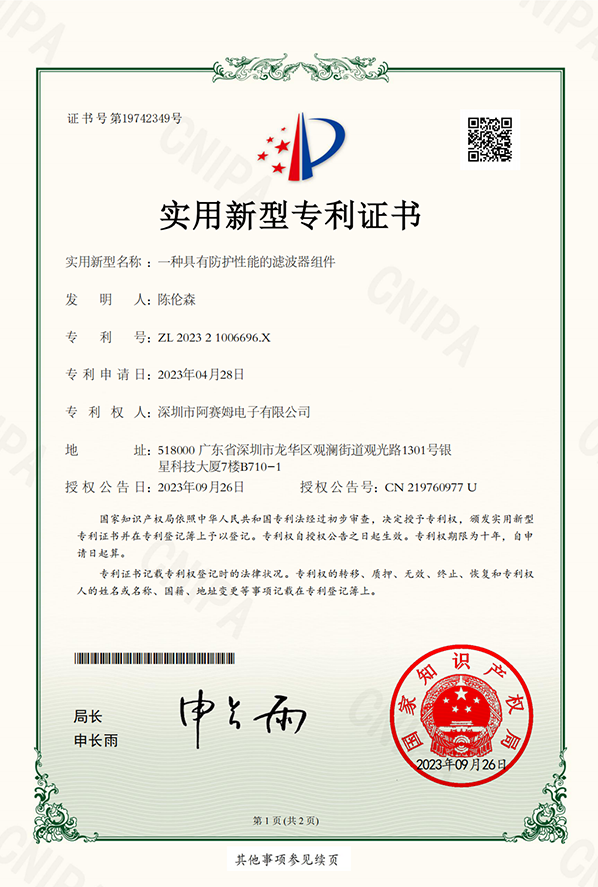

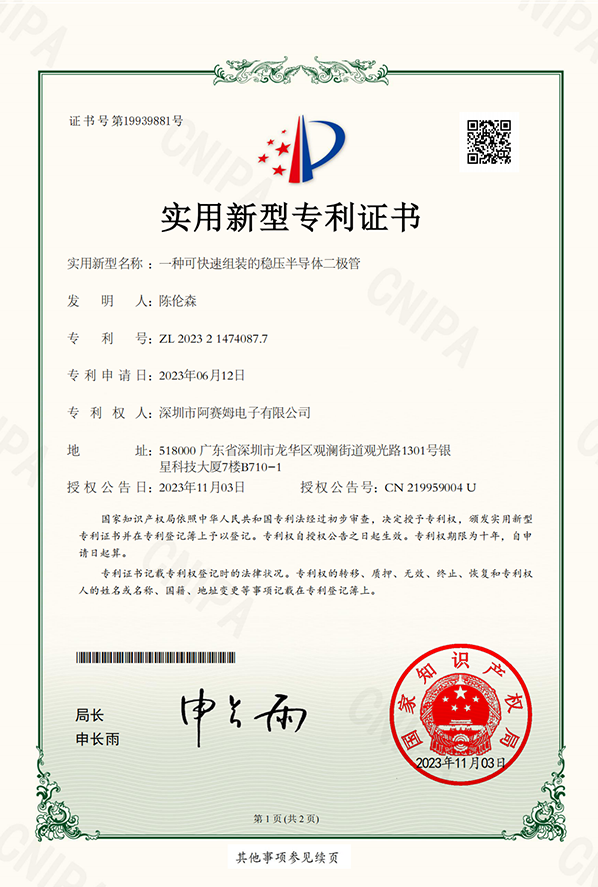

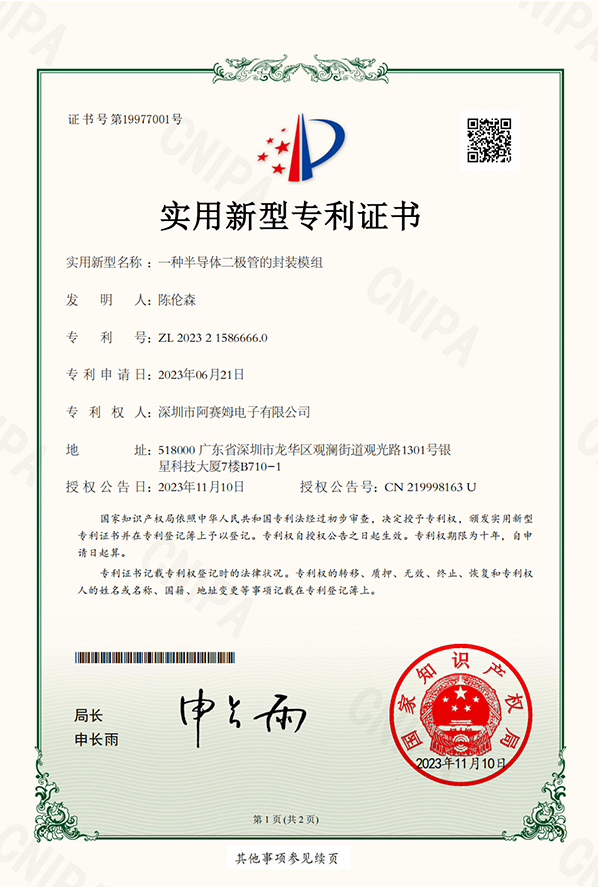

International standardcertification

All of our production sites have been certified by ISO9001 and ISO/ISO45001.

All policies related to sustainability, health, safety and environmental protection have been integrated into our philosophy, and our production sites have also been certified by ISO14001 and ISO45001.

The products produced also meet environmental protection requirements and comply with EU standards such as RoHS, HF and REACH