How to effectively dissipate heat and solve the problem of severe heating of MOSFETs? - Shenzhen ASIM

Mosfet overheating analysis and Efficient Heat Dissipation solutions

Based on thermodynamic principles and device documentation (such as "M050N03J REV1.1"), this paper analyzes the causes of the heating core of MOSFETs, provides verified heat dissipation design methods through actual measurement, covering package thermal resistance optimization, PCB layout criteria, and heat sink selection parameters, to solve the overheating failure problem in power supply/motor drive.

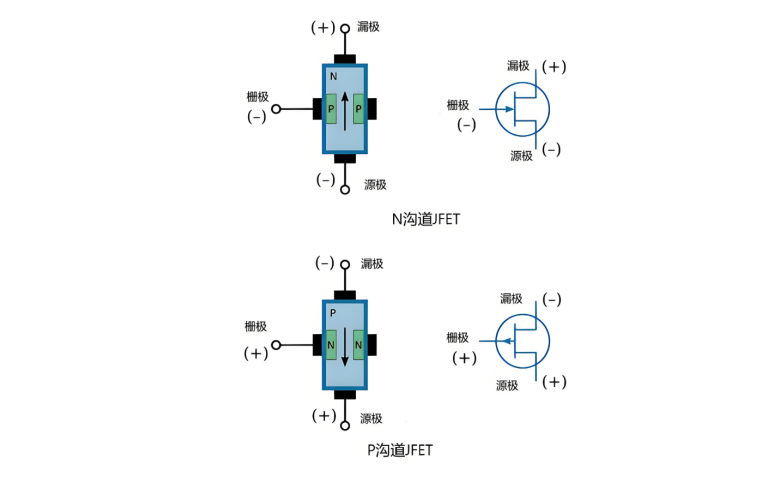

一、The source of heat generation and thermodynamic model

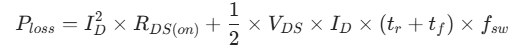

Loss composition formula

- Conduction loss:Dominant low-voltage high-current scenarios (such as RDS(on)=1.8mΩ@10V for M050N03J)

- Switching loss:Dominate high-voltage and high-frequency scenarios (such as 100V/1MHz applications)

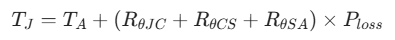

Junction temperature calculation

- RθJC:Thermal resistance from junction TO shell (typical value of TO-220:1.5℃/W)

- RθSA:Radiator thermal resistance (forced air cooling can be reduced to 0.5℃/W)

- Key parameters:

Data source:ASIM Document "M050N03J"

二、Hardware-level heat dissipation solution

1. Packaging and thermal interface optimization

Thermal grease coating

| Measures | Effect | Key Points of implementation |

|---|---|---|

| Low thermal resistance packaging | D2PAK has a 40% lower thermal resistance than TO-220 | Preferred LFPAK/DirectFET packaging (RθJC<0.8℃/W) |

| Reduce RθCS to 0.1℃/W | Thickness ≤0.1mm, pressure >10psi | |

| Application of phase Change Materials | Its thermal resistance is 30% lower than that of silicone grease | Tm≥80℃ |

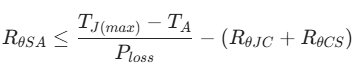

2. Radiator selection formula

Case:

- M050N03J operates at 30A/10V (Ploss=16.2W), TA=50℃

- Demand RθSA ≤ (150-50)/16.2 - (1.5+0.2) ≈ 3.7℃/W

三、PCB layout heat dissipation design

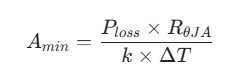

Calculation of copper foil area

- k:The thermal conductivity of copper (400W/m·K for 1oz of copper)

- ΔT:Allowable temperature rise (usually ≤30℃)

- Minimum heat dissipation area:

Key layout rules

- Source copper plating: Use 2oz copper thickness + grid copper plating (reduce thermal resistance by 15%)

- Via array: Φ0.3mm via spacing 1.2mm (Double-sided thermal conductivity increased by 40%)

- Thermal symmetry design: When multiple pipes are connected in parallel, ensure that the temperature difference between each pipe is ≤5℃ (ASIM Document "M120N06JC")

四、System-level cooling strategy

1. Optimization of driving parameters

| Parameter | Influence | Adjustment plan |

|---|---|---|

| Gate resistance Rg | Reduce switching losses | According to the ASIM document "M050N03J" |

| Switching frequency fsw | High frequency increases switching loss | The optimal value is determined by measuring the temperature rise (usually 50-200 KHZ). |

| Dead zone time | Too short causes a direct current | It is recommended to be ≥100ns |

2. Forced heat dissipation scheme

- Air-cooled design:

- When the wind speed is greater than 3m/s, the thermal resistance decreases by 50%

- Priority axial flow fan

- Liquid cooling application:

- The thermal resistance of the cold plate is as low as 0.05℃/W (suitable for modules over 500W)

五、Case Analysis of Overheating Failure

Case 1: The MOS of the motor controller of an electric tool was burned out

- Phenomenon: After continuous operation for 10 minutes, TJ>160℃

- Root cause analysis:

- PCB single-layer copper foil (1oz) without heat dissipation vias (measured RθJA=65℃/W)

- Insufficient gate drive voltage (VGS=8V causes RDS(on) to increase by 30%)

- Rectification plan:

- Change to 2oz copper + add 12 Φ0.3mm vias (RθJA reduced to 38℃/W)

- Upgrade VGS to 10V (ASIM Document "M050N03J")

六、Design verification process

- Thermal simulation:

- Verify the junction temperature using ANSYS Icepak (error<5%)

- Measurement method:

- The shell temperature TC is measured by an infrared thermal imager

- Calculate the junction temperature:TJ = TC + Ploss × RθJC

- Regulations for reducing the limit:

- Industrial grade:TJ ≤ 125℃(MAX the value 80%)

- Automotive grade: TJ ≤ 110℃ (required by AEC-Q101)

Conclusion

Effective heat dissipation requires the coordinated optimization of the four-layer design of "component selection - thermal interface -PCB- driver parameters"

- Give priority to packages with RθJC<1.5℃/W (such as LFPAK)

- When forced air cooling is applied, the RθSA of the radiator is strictly calculated according to the formula

- The PCB layout adopts a 2oz copper thickness + via array

Warning: A junction temperature exceeding 150℃ will cause avalanche failure (ASIM Document "M050N03J")